B21, China Town Mall, Midrand

Automatic Sachet Food Filling Multi-function Packaging Machine

- Section : Appliances

- Category : Food Filling Machines

- SKU : 1600685621110

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of food products can the Automatic Sachet Food Filling Multi-Function Packaging Machine handle?

The machine is multi-function and can package powders (e.g., spices, flour, sugar), granules (e.g., rice, seeds), liquids (e.g., sauces, oils, juices), and solid items (e.g., candies, nuts).

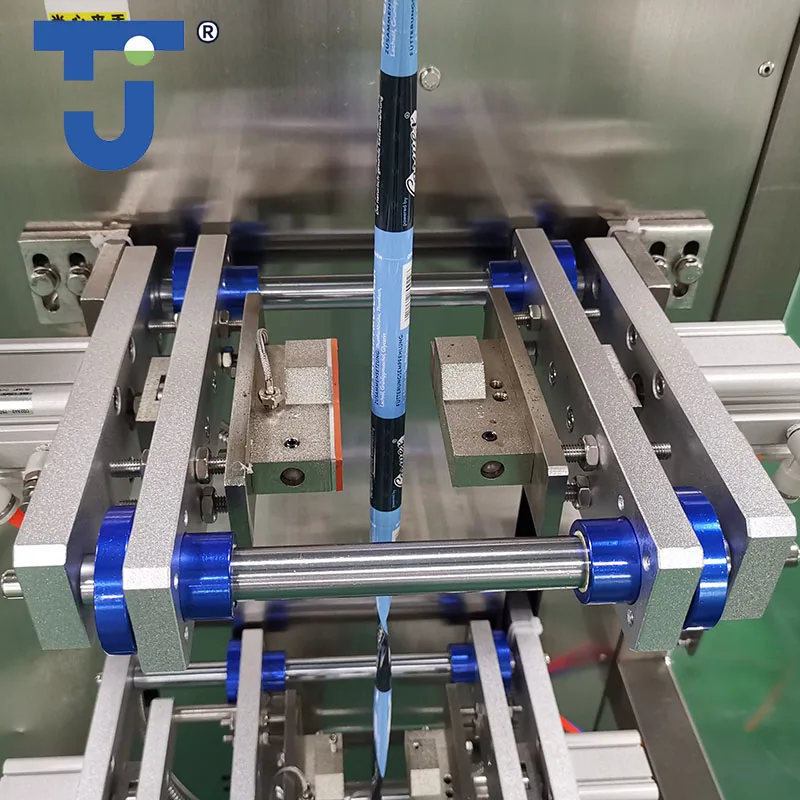

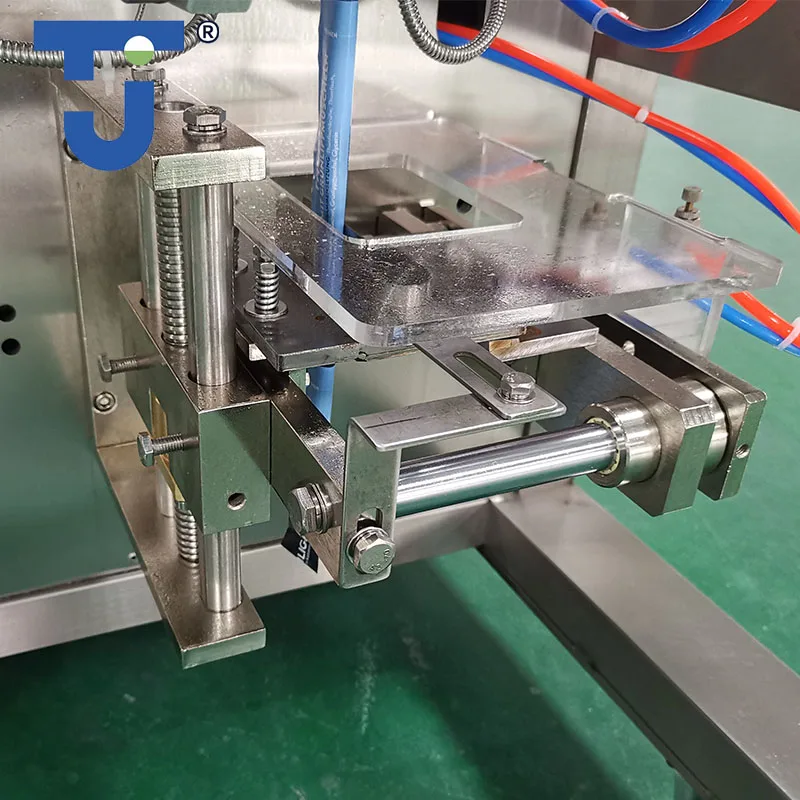

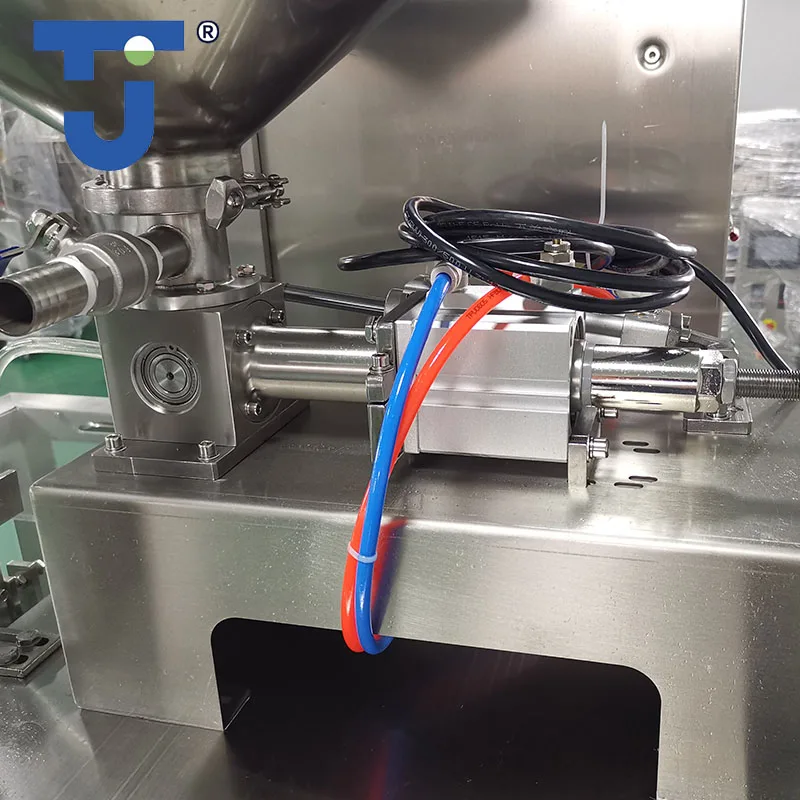

2. What is the model and main drive/sealing technology of the machine?

The listed model is DF-50BYC. It is pneumatic-driven with a piston filling system and uses back heat-sealing technology for secure sachet seals.

3. What are the packing range and bag size capabilities?

Filling volume range is 2–100 ml. Supported bag dimensions are length 50–200 mm and width 20–100 mm (custom sizes can be configured within those ranges).

4. What is the machine's production speed?

Typical packing speed is 35–50 bags per minute, depending on product characteristics, sachet size and material, and operation settings.

5. What are the machine's electrical and power requirements?

Specification shows 220 V, 50/60 Hz electrical supply with total power approximately 2.5 kW. Exact power hookup and protection should be verified with your electrical technician or supplier.

6. What materials can the machine use for packaging films and pouches?

It can accommodate a variety of film materials including aluminum (AL), paper, and laminates such as OPP/CPP, PET/PE, PA, and EVOH. It also supports commonly used pouch/film structures for food applications.

7. What is the machine construction and is it food-hygienic?

The machine body is constructed from stainless steel SUS 304, offering corrosion resistance and easy cleaning to meet common food hygiene standards. Smooth surfaces and removable parts facilitate sanitation.

8. How user-friendly is the control system and does it provide monitoring?

The machine includes an intuitive control panel for adjusting fill volume, sachet dimensions and production speed. The control system provides real-time feedback such as fill levels and sealing status to help maintain continuous operation.

9. How easy is maintenance and cleaning?

Design features include removable parts and smooth stainless surfaces for quick cleaning and routine maintenance. Regular cleaning schedules and spare-part checks are recommended to ensure optimal performance.

10. Can the machine handle custom sachet sizes and different production recipes?

Yes — settings for filling size, sachet dimensions and production speed are adjustable, enabling rapid changeovers and customization for various product recipes and package formats.

11. Is the machine energy efficient and suitable for small production spaces?

Yes — it is designed with a compact footprint (approx. 1000 × 800 × 2000 mm) and energy-efficient operation to reduce operational costs and fit into small to medium production areas.

12. What are the machine weight and physical dimensions?

The machine weighs approximately 400 kg with overall dimensions listed as 1000 mm (L) × 800 mm (W) × 2000 mm (H).

13. What support, installation or training is available?

Installation, commissioning and operator training are typically provided by the supplier or distributor. Contact your sales representative for details on on-site setup, training packages and after-sales support.

14. Are there considerations for packaging heat- or shear-sensitive products?

Because the machine uses heat sealing and pneumatic/piston filling, you should review sealing temperatures, filling speeds and suitable film materials for heat-sensitive or shear-sensitive products. Consult the supplier to determine appropriate parameters and film choices.

15. How do I get warranty, spare parts and service information?

Warranty terms, spare-parts availability and service contracts vary by supplier and region. Ask your sales contact for the machine's warranty policy, recommended spare parts list and available maintenance/service plans.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading