B21, China Town Mall, Midrand

Automatic rotary doypack packing machine sauce filling machine

- Section : Machinery

- Category : Filling Machines

- SKU : 1600362417625

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

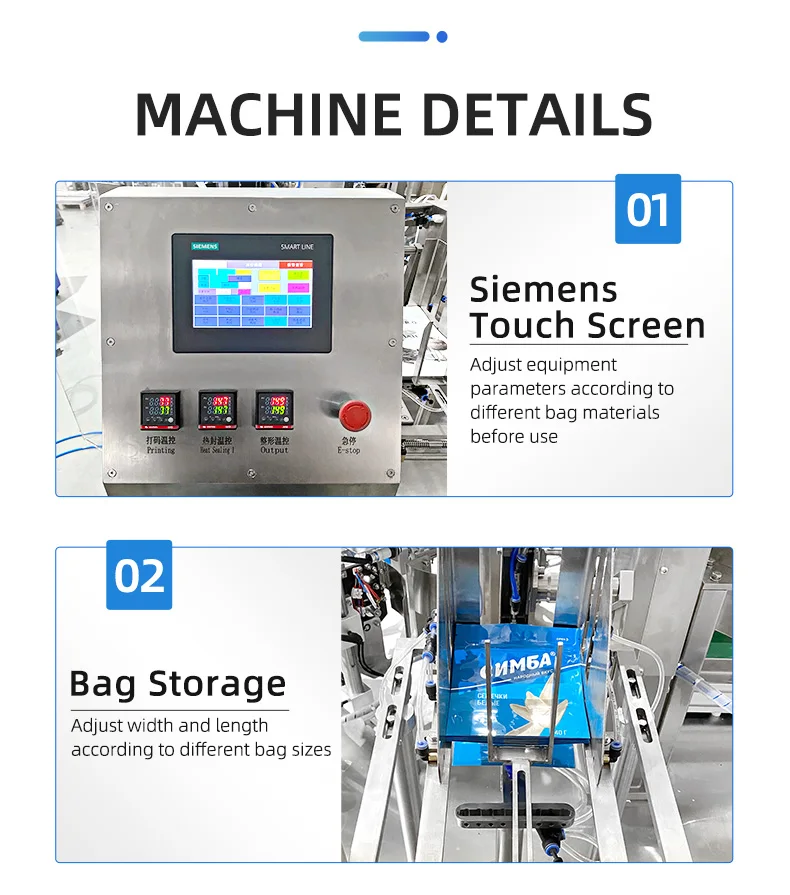

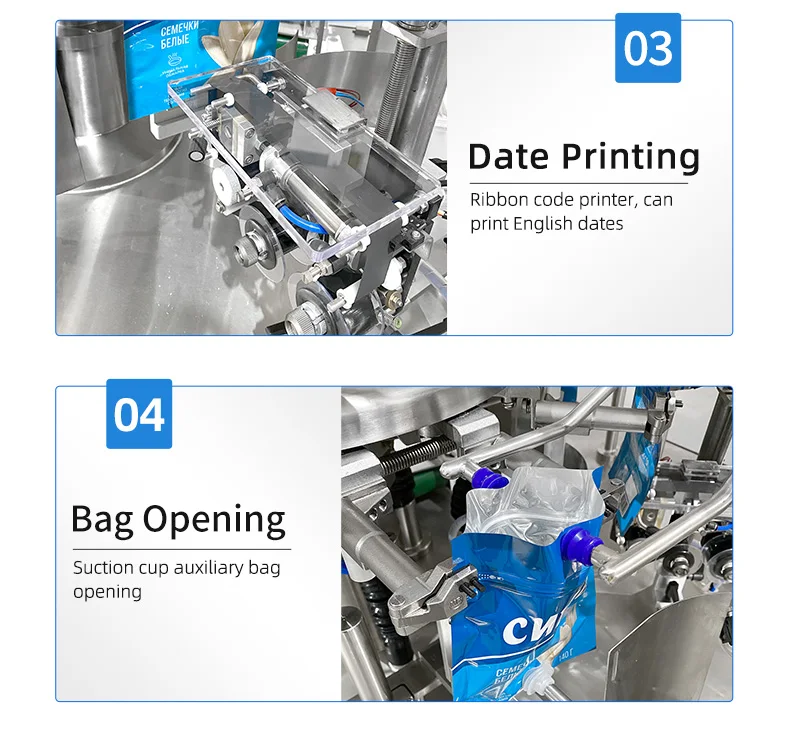

1. What is the "Automatic rotary doypack packing machine sauce filling machine"?

A fully automatic rotary filling and packing machine designed to fill and seal premade doypack pouches with liquids and powders (sauces, honey, juices, detergents, milk powder, spices, etc.). It integrates rotary indexing, PLC control, and high-accuracy filling for high-speed production.

2. Which products can this machine handle?

Liquids and semi‑viscous liquids (ketchup, sauces, honey, oil, water), beverages (juice, chocolate drink), liquid detergents/soaps, and powders or mixed powders (milk powder, protein powder, coffee, spices, washing powder).

3. What are the machine's capacity and speed options?

Available capacity options are 4000 BPH, 6000 BPH, and 8000 BPH. Packing speed is adjustable roughly between 10–60 bags per minute depending on pouch size, product viscosity, filling volume and selected model.

4. What filling accuracy can I expect?

The machine delivers a filling accuracy of approximately ±1% (error) under normal operating conditions and with correct setup.

5. What pouch types and film materials are supported?

Designed for premade bags including doypack style pouches. Compatible film/laminate materials include OPP/CPP, OPP/CE MST/PE and PET/PE.

6. What are the machine's main materials and components?

Machine contact parts are food‑grade stainless steel SUS304. Core components include pressure vessel, pump, PLC, gears, bearings, gearbox and electric motor.

7. What are the machine dimensions and footprint?

Standard machine dimensions are approximately 1150 mm (L) x 1795 mm (W) x 1650 mm (H). Actual footprint and layout requirements should be confirmed with sales for factory layout and installation planning.

8. What power supply and drive type does it use?

The machine is electrically driven. Exact voltage, phase and power requirements depend on model and regional standards — please provide local power specs so we can confirm electrical configuration.

9. Can the machine handle high‑viscosity products like honey or ketchup?

Yes. The machine supports viscous products, but high‑viscosity items may require specific pump types (gear, piston) or options such as heated hoppers and slow fill parameters. Specify your product viscosity during inquiry so the correct configuration can be supplied.

10. How easy is changeover between different pouch sizes or products?

The machine is modular with adjustable fixtures and PLC control. Changeover is achieved by replacing small fixtures and adjusting recipes in the PLC; actual changeover time depends on pouch sizes and product differences. Quick‑change options are available to minimize downtime.

11. What cleaning and maintenance are required?

Regular cleaning of product contact parts, periodic lubrication of drive parts, and routine inspection of seals and pumps are recommended. Modules can be separated for cleaning, and the machine is designed for straightforward maintenance. A maintenance schedule and Lubrication/Cleaning guidelines are provided.

12. What warranty and after‑sales support are provided?

Standard warranty is 1 year. The supplier provides machinery test reports, outgoing inspection video, spare parts support and technical assistance. Installation, commissioning and operator training can be arranged (onsite or remote) — contact sales for details.

13. How is the machine packaged and shipped?

Standard export packaging: modules dedusted/cleaned and lubricated, wrapped with plastic film, then packed into plywood/wooden cases with waterproof PO film. Custom packaging can be arranged based on customer requirements.

14. Are certifications (CE/ISO/Food safety) available?

Relevant certifications are not listed in the basic specification. Certification and compliance documentation (such as CE or other certificates) can usually be provided on request — please state required certificates when inquiring.

15. How do I order and what is the typical lead time?

Contact the supplier/sales with your product details (type, viscosity, pouch size, required capacity, power specs). Lead time depends on configuration and order queue; typical production lead time is generally around 30–60 days but confirm current lead time with sales.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading