B21, China Town Mall, Midrand

Automatic Multi-Purpose Filling Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601029097484

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

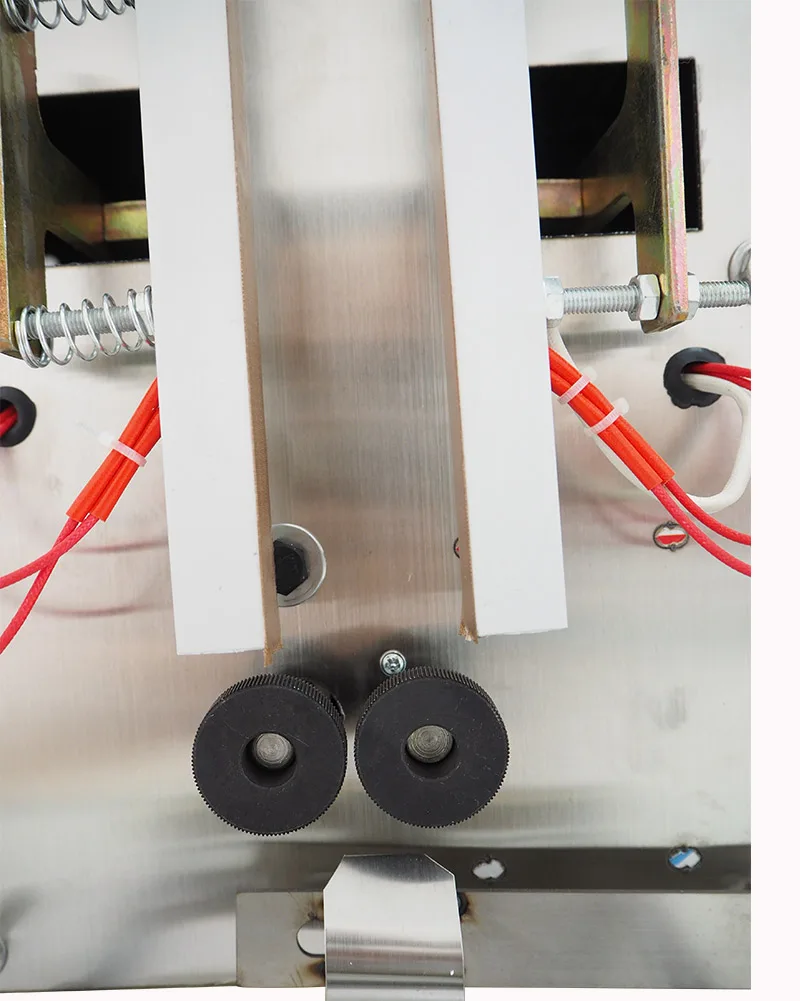

1. What is the Automatic Multi-Purpose Filling Machine and what applications is it suited for?

The Automatic Multi-Purpose Filling Machine (model YL-SP100T) is an electrically driven automatic packing machine designed for efficient filling and three-side sealing of small bags. It's suited for industries like food, beverage, commodity, and chemicals for packing powders, granules, small solids and similar free-flowing materials. For specialized liquids, pastes or highly viscous products, please consult the supplier for compatible attachments or a different model.

2. What are the key technical specifications of model YL-SP100T?

Model YL-SP100T specifications include: voltage 220V/110V (50/60Hz), rated power 500W, packing range 2–100 g, sealing type three-side sealing, accuracy/error range 1–2 g (material-dependent), packing speed 10–15 bags/min (product-dependent), maximum film width 18 cm (customizable), maximum bag length 16 cm, machine size 47.5 × 36.5 × 163.5 cm, and weight approximately 70–80 kg depending on configuration.

3. What types of products can I pack with this machine?

The machine is optimized for powders, granules, seeds, small solids, and similar free-flowing materials within the 2–100 g range. It can handle some non-free-flowing products with appropriate dosing attachments; for liquids, pastes or highly viscous products, ask the manufacturer about compatible filling heads or alternative models.

4. How accurate is the filling and what affects accuracy?

Typical accuracy is within 1–2 g, but actual accuracy depends on product characteristics (particle size, bulk density, moisture, flowability) and environmental factors. Calibration and correct dosing setup are important to achieve optimal accuracy.

5. What is the machine's production capacity (bags per minute)?

Typical packing speed is 10–15 bags per minute. Actual throughput depends on fill weight, product characteristics, operator setup, and the selected packaging film.

6. What packaging formats and film specifications are supported?

The machine produces three-side sealed pouches. Standard max film width is 18 cm (customizable). Maximum bag length is 16 cm. For other bag sizes, formats or custom film widths, consult the manufacturer about possible modifications.

7. What power supply and drive type does the machine require?

The machine is electrically driven with a rated power of 500 W. It supports 220V or 110V at 50/60 Hz depending on the ordered configuration.

8. How heavy is the machine and what are its dimensions?

Machine dimensions are approximately 47.5 × 36.5 × 163.5 cm. Weight varies with configuration—model YL-SP100T is listed at about 70 kg, and the product description cites a heavy-duty construction around 80 kg; actual shipping weight depends on accessories and packing.

9. What maintenance and cleaning are required?

Regular maintenance includes daily cleaning of contact parts and dosing surfaces, routine lubrication of moving parts per the manual, periodic inspection and replacement of wear parts (seals, belts, blades), and calibration checks. Follow the supplied maintenance schedule and operate cleaning with power disconnected.

10. What support is provided after purchase?

The machine comes with video technical support and online assistance for troubleshooting, setup and operation. For on-site service, spare parts or extended support packages, contact the supplier to arrange terms.

11. Are spare parts and consumables available?

Yes. Common spare and wear parts include sealing jaws/blades, sensors, belts, electrical components and dosing parts. Availability and delivery times vary—order spare parts through your supplier or authorized dealer.

12. Can the machine be customized for different products or capacities?

Yes. The machine supports some customization such as film width, dosing attachments and optional accessories to handle different product types. Contact the manufacturer with your product details to discuss feasible modifications.

13. What safety features should operators expect?

Standard safety features typically include emergency stop, electrical grounding, protective covers around moving parts and safety interlocks. Operators should be trained, use personal protective equipment as needed, and follow the safety instructions in the user manual.

14. Is installation and operator training provided?

Basic installation guidance, setup instructions and remote/video training are provided. For onsite installation or extended operator training, contact the supplier to arrange services (may incur additional charges).

15. How do I get pricing, lead time and warranty information?

Pricing, lead times and warranty terms vary by region, configuration and order quantity. Contact the sales team or authorized distributor with your required specifications and destination to receive a formal quote and details on warranty coverage.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading