B21, China Town Mall, Midrand

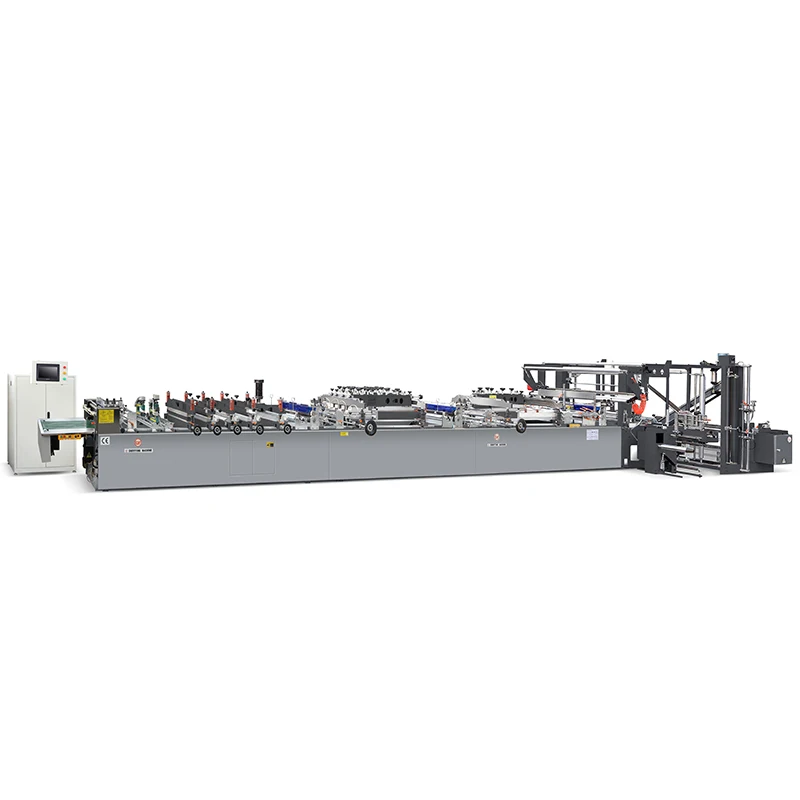

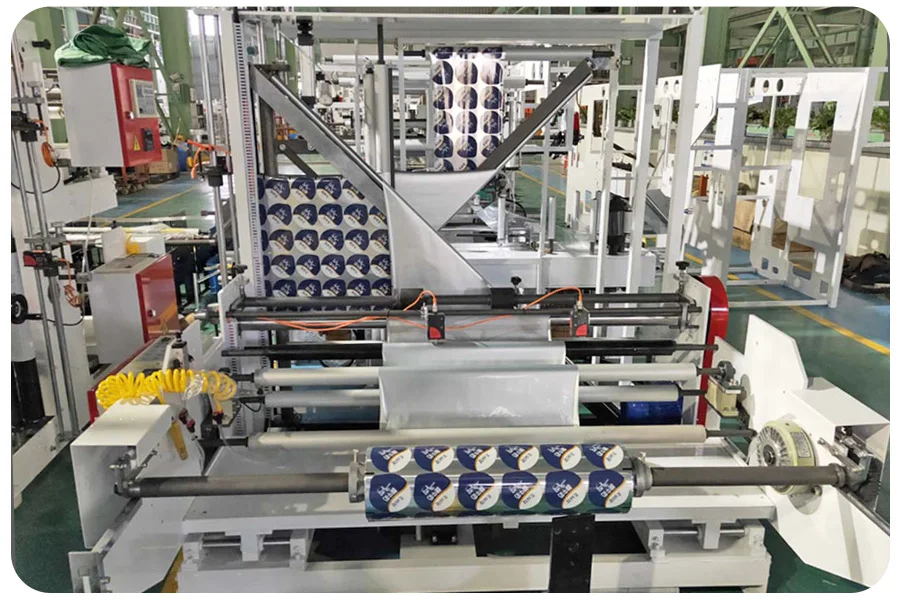

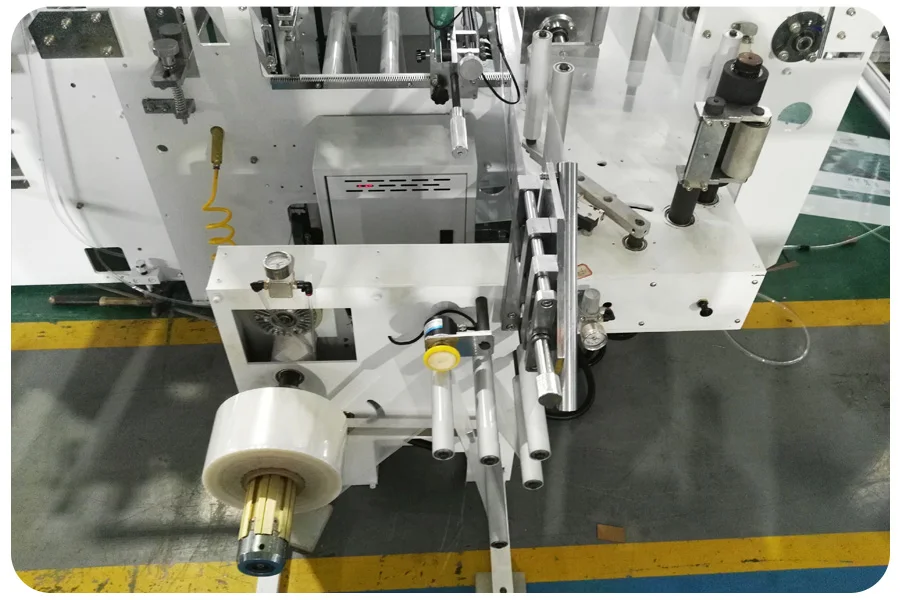

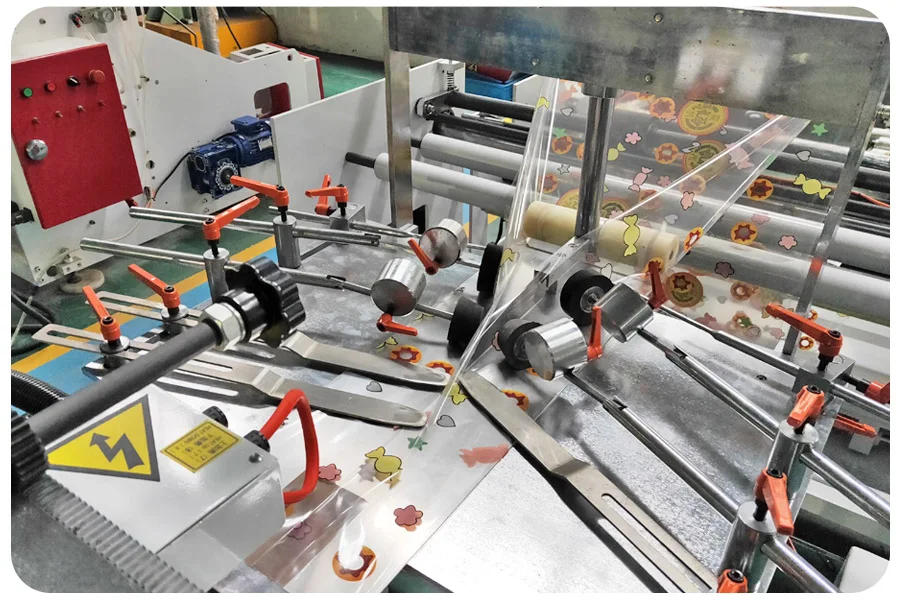

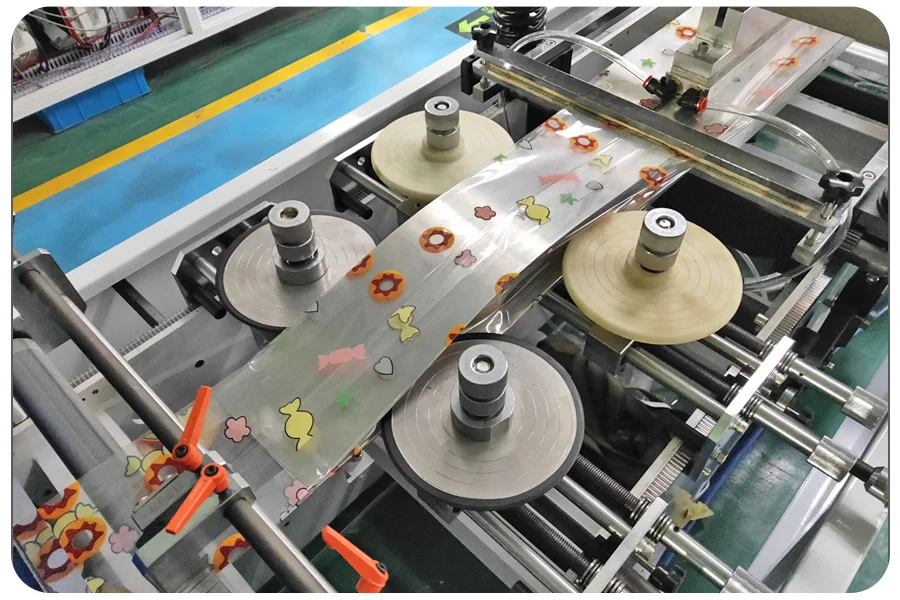

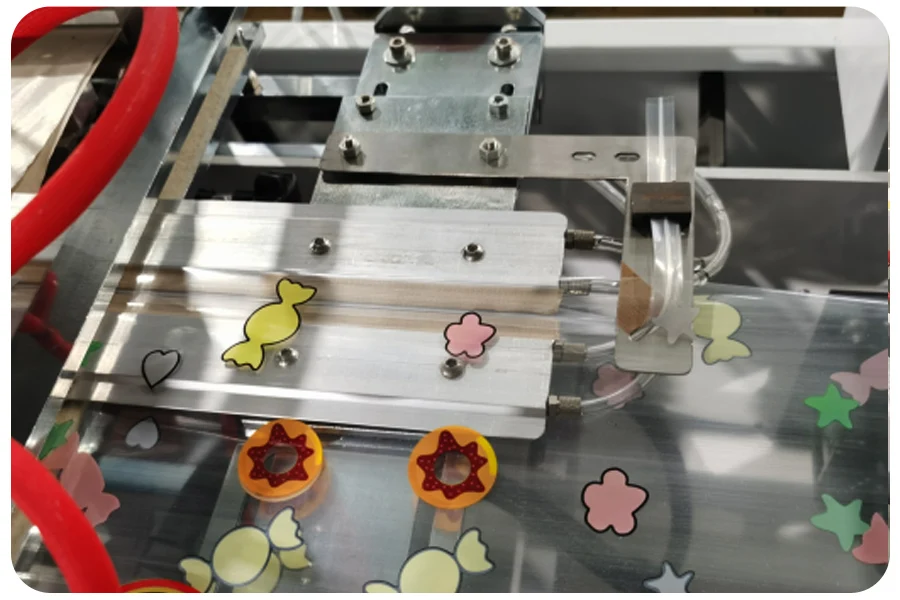

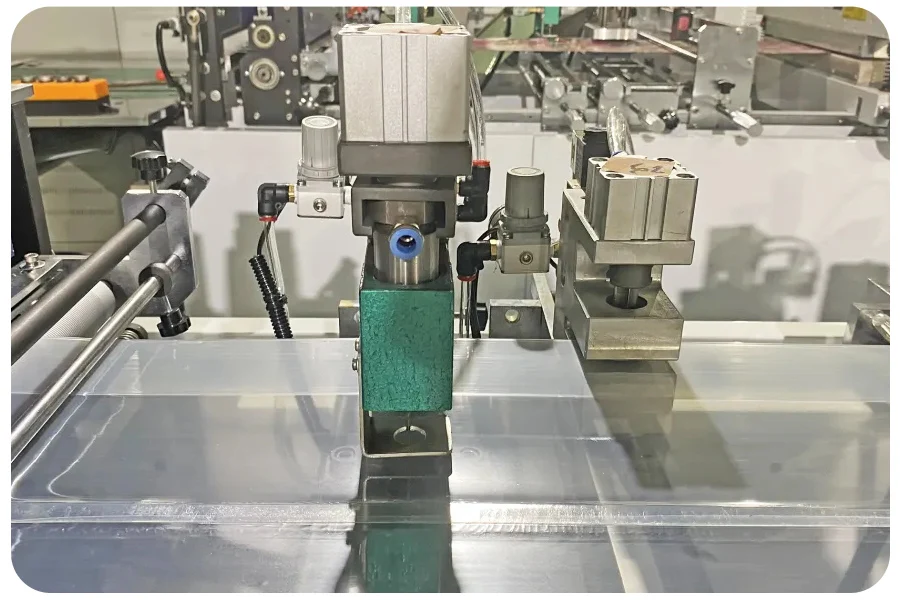

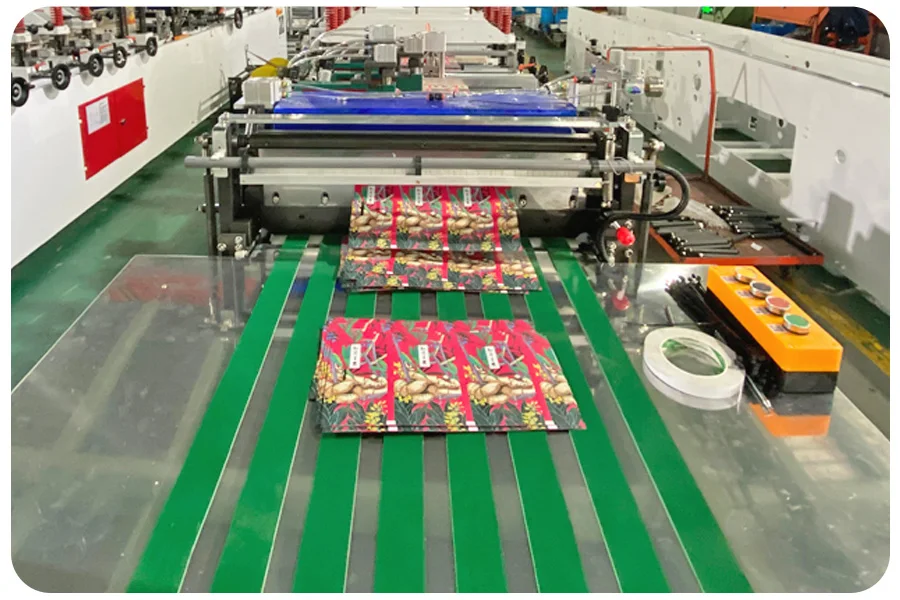

Automatic Multi-Function Pouch Making Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600215680973

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of pouches can the Automatic Multi-Function Pouch Making Machine produce?

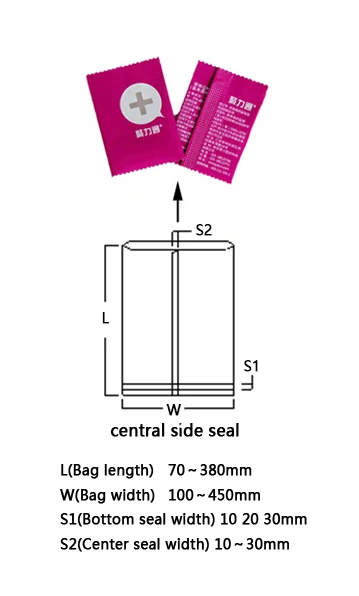

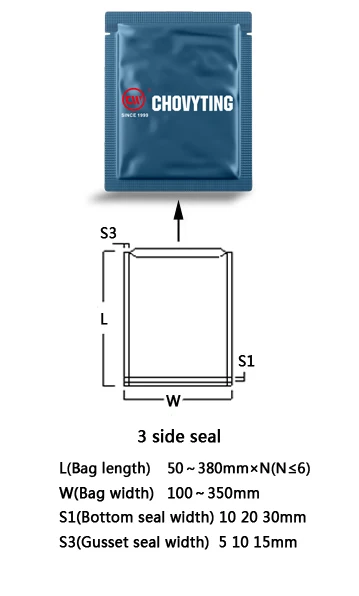

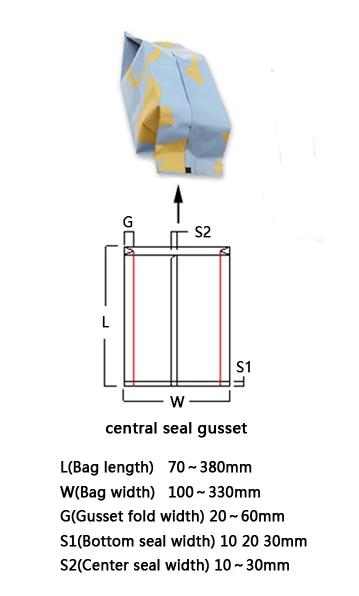

The machine can create various types of pouches including central seal, gusset, doypack, and zipper pouches.

2. What is the maximum speed of the pouch making machine?

The Automatic Multi-Function Pouch Making Machine operates at a maximum speed of 30 meters per minute.

3. What materials can this machine handle?

The machine is capable of processing PET, PE, and OPP laminated materials, making it versatile for diverse packaging needs.

4. Is the pouch making process fully automated?

Yes, the machine features advanced automation for fully automatic operation, streamlining the pouch-making process.

5. What are some key components of the machine?

The machine includes premium components such as a CPG motor from Taiwan, Yasakwa servo motor from Japan, and a Weinview touch screen from Taiwan.

6. What is the pouch-making height range for different pouches?

The pouch-making height ranges from 70-380mm for 3 sides seal/center seal pouches and from 100-500mm for stand up and zipper bags.

7. Can I customize the cutting knife for this machine?

Yes, the cutting knife can be customized; it uses a scissor type knife or can be adapted to a fly knife cutting system.

8. Does the machine come with any support or documentation?

Yes, it includes a machinery test report, video outgoing inspection, and video technical support for comprehensive assistance.

9. What is the recommended pouch-making width for different seal types?

The recommended widths are 70-580mm for 3 sides seal, 100-200mm for 4 sides seal, and up to 450mm for center seal pouches.

10. What is the warranty period for the Automatic Multi-Function Pouch Making Machine?

Please refer to the manufacturer's warranty policy for specific details regarding the warranty period and coverage.

11. Is a double unwinder option available?

Yes, the machine offers an optional double unwinder, which is suitable for vacuum pouches.

12. What types of punching devices are included with the machine?

The standard punching devices include easy tear holes and round holes (diameters of 6, 8, and 10 mm), with an optional handle punch available.

13. How many pouches can the machine produce per minute?

The machine is capable of producing between 100 to 170 pouches per minute, depending on the specific setup.

14. Does the machine support secondary film inserting?

Yes, it is equipped with a secondary film inserting and pouching unit for forming the stand-up pouch bottom part.

15. What industries can benefit from using this pouch making machine?

This machine is ideal for businesses in various industries that require high-quality packaging solutions, such as food, cosmetics, and pharmaceuticals.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading