B21, China Town Mall, Midrand

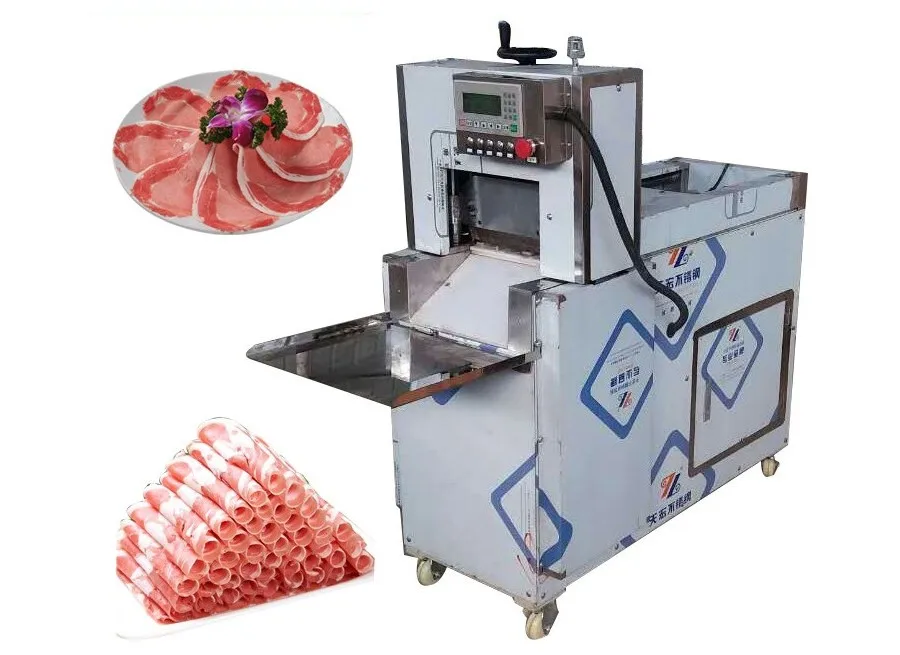

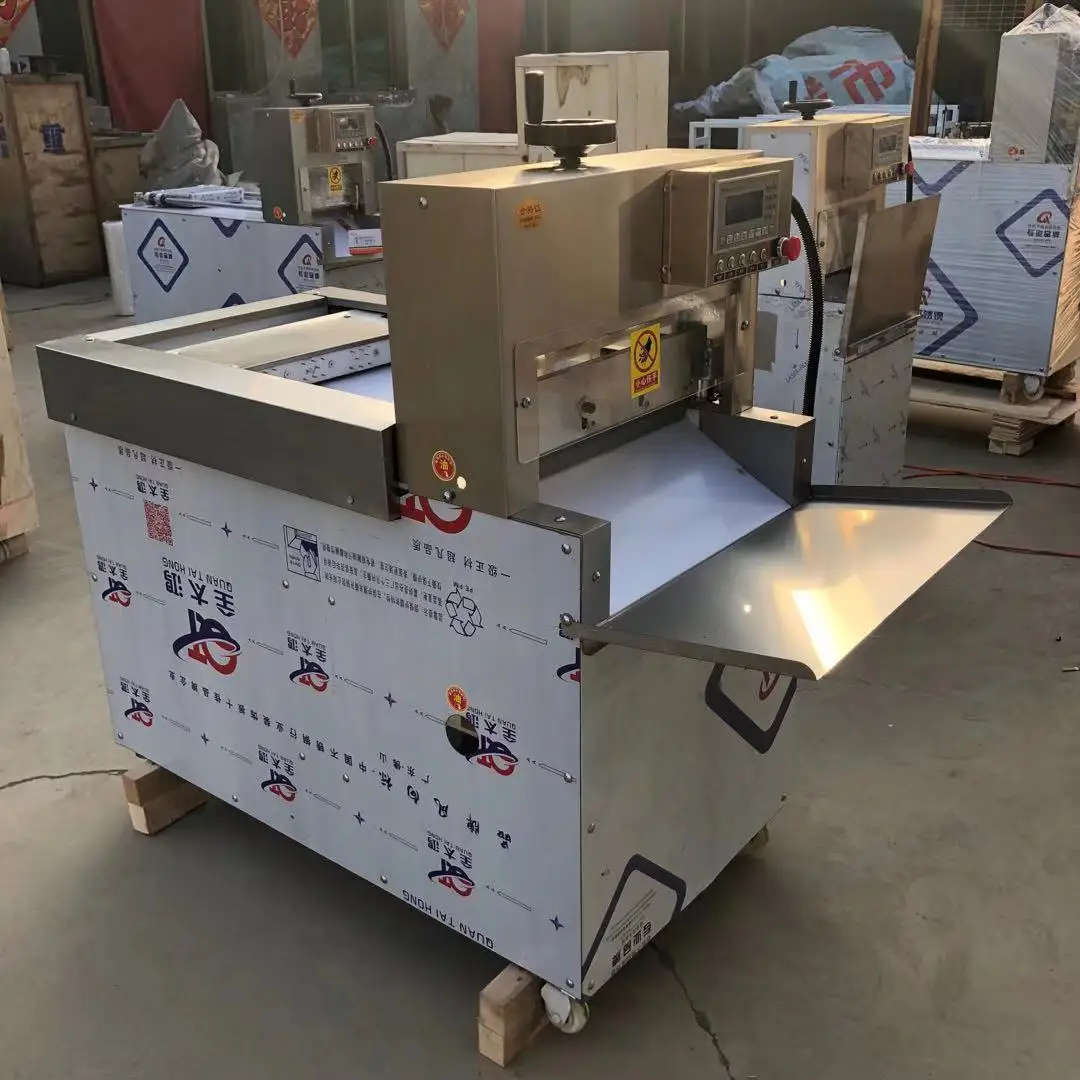

Automatic Meat Processing Machine Frozen Meat Slicer

- Section : Machinery

- Category : Meat Slicers

- SKU : 1600411967966

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of meat can the Automatic Meat Processing Machine Frozen Meat Slicer handle?

This slicer is designed to process various types of frozen meats, including bacon, ham, and beef.

2. What is the slicing capacity of this machine?

The machine can slice between 600 to 750 kg of meat per hour, making it suitable for high-demand environments.

3. How thick can the slices be cut?

The slicer allows for adjustable cutting lengths ranging from 15 to 50 mm, accommodating a variety of meat preparations.

4. Is the machine safe to use?

Yes, the Automatic Meat Processing Machine is constructed from food-grade stainless steel, ensuring durability and safety during operation.

5. What is the power rating of the machine?

The machine is equipped with a powerful 3kw motor that provides fast and consistent slicing performance.

6. How many pieces can the machine slice per minute?

The slicer can efficiently slice up to 120 pieces per minute.

7. Can this machine operate automatically?

Yes, it features automatic operation, which helps save on labor costs in busy environments.

8. How does the double guide propulsion system work?

The double guide propulsion system ensures uniform processing of meat, enhancing slicing efficiency and consistency.

9. What is the minimum temperature at which the machine can slice meat?

The slicer can process meat that is 18 degrees below zero without thawing, ensuring that the meat maintains its integrity while being sliced.

10. How easy is it to clean the machine?

All cutting parts of the machine are designed for easy cleaning, ensuring proper hygiene and maintenance.

11. What are the dimensions and weight of the machine?

The dimensions and weight vary by model. For example, the MS-10 model measures 950x350x400 mm and weighs 80 kg.

12. Can the machine slice meat into various shapes and sizes?

Yes, it can cut frozen meat into thick, thin, long, straight pieces, and various volume types, making it multifunctional.

13. What kind of maintenance does the machine require?

Routine maintenance includes regular cleaning of the cutting parts and ensuring that the motor and conveyor are in good working condition.

14. Is this machine suitable for home use?

The Automatic Meat Processing Machine is primarily designed for commercial use in restaurants and meat processing businesses due to its high capacity.

15. What are the different models available?

The machine comes in several models including MS-10, MS-20, MS-40, MS-60, and MS-80, each varying in power, capacity, and size.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading