B21, China Town Mall, Midrand

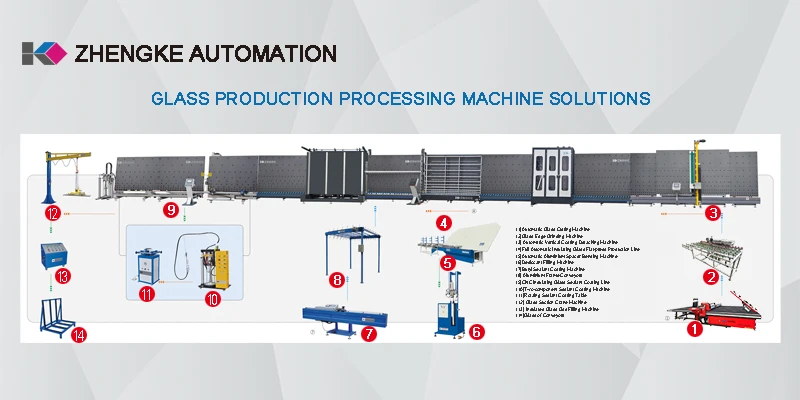

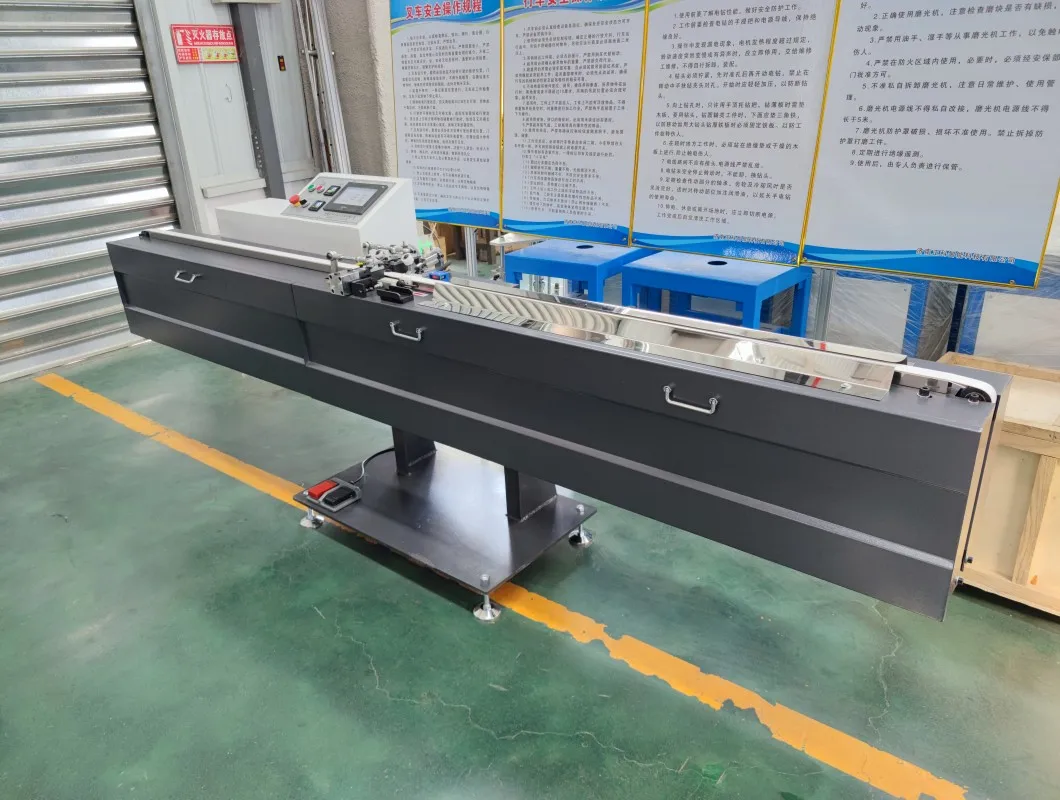

Automatic Butyl Extruder Insulating Glass Processing Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 10000019006523

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the Automatic Butyl Extruder Insulating Glass Processing Machine?

The main function of this machine is to automate the process of sealing insulating glass units using butyl sealant, improving efficiency and precision in glass production.

2. What types of machinery are included in this production line?

The production line includes various machines such as a glass cutting machine, edge grinding machine, coating machines, desiccant filling machine, and aluminum spacer bending machine, among others.

3. How does the touch screen control system enhance operation?

The touch screen control system simplifies operation by providing a user-friendly interface that allows for easy navigation and control of the machine settings.

4. What is the speed range of the machine?

The machine offers a delivery speed that can be adjusted between 15 to 30 meters per minute, with speed settings from 1 to 5.

5. Can the glue dispensing system be adjusted?

Yes, the advanced auto-dispensing system can be adjusted for glue thickness within the range of 6 to 18.5 mm.

6. What are the benefits of using a pneumatic pump system?

The pneumatic pump system provides stable pressure, enhances energy efficiency, and ensures consistent performance throughout the operation.

7. What is the capacity of the glue container?

The large-size plastic cylinder can hold up to 14 kg of glue, allowing for longer operational periods without frequent refills.

8. Is there an option for height adjustment on the table?

Yes, there is an optional type of table that can be lifted to accommodate different operational needs.

9. How does the PC control system improve production?

The PC control system automates positioning, transmission, and glue coating, resulting in increased accuracy and reduced manual intervention.

10. What is the purpose of the glass suction crane machine?

The glass suction crane machine is designed to safely lift and move glass panels during processing, enhancing safety and efficiency.

11. Does the machine support two-component sealant?

Yes, the machine includes a two-component sealant coating option for applications that require a more durable seal.

12. What safety features are included in the machine?

The machine is designed with various safety features, including emergency stop buttons and protective covers to ensure operator safety during operation.

13. What maintenance is required for the machine?

Routine maintenance includes checking and replacing seals, cleaning the dispensing system, and ensuring that all mechanical parts are lubricated and functioning properly.

14. Is training provided for operating the machine?

Yes, comprehensive training is typically provided to ensure operators are familiar with all functions and safety protocols of the machine.

15. What is the lead time for delivery after placing an order?

Lead time for delivery can vary based on order volume and customization, but typically ranges from 4 to 8 weeks.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading