B21, China Town Mall, Midrand

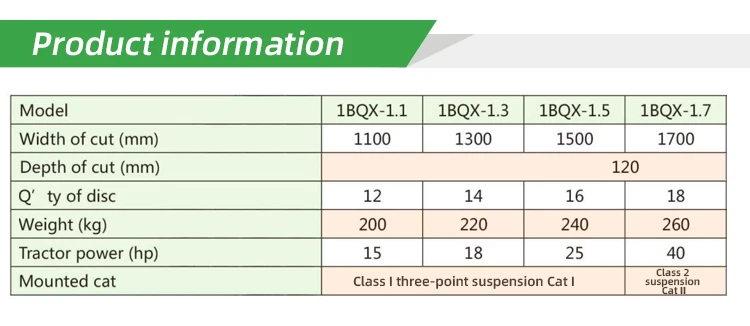

Agricultural 24 Blades 60Hp Farm Disc Plough Machine Tractor Three Point Mounted Disc Harrow Disc Harrow

- Section : Machinery

- Category : Cultivators & Ploughs

- SKU : 1600638782433

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is this product?

This is a three-point mounted agricultural disc harrow/plough with 24 discs designed for soil breaking, residue incorporation and seedbed preparation for tractors around 60 HP.

2. How many blades/discs does it have and what does that mean?

It has 24 blades (discs). More discs increase working width and soil disturbance; the actual working width depends on disc diameter and spacing—refer to the seller's specification sheet for exact width.

3. What tractor power is required to operate it?

The unit is specified for use with tractors around 60 HP. Ensure your tractor has sufficient drawbar and hydraulic capacity for safe operation and transport.

4. What type of hitch is used to attach this harrow?

It is three-point mounted (standard Category I or II depending on model). Confirm the hitch category and pin spacing with the supplier to ensure compatibility with your tractor.

5. Is the gang angle or working depth adjustable?

Most three-point disc harrows have adjustable gang angle and working depth (via top link, lift arms or gauge wheels). Check the product manual or ask the seller for the specific adjustment mechanisms on this model.

6. What are the discs made of and are they replaceable?

Discs are typically made of hardened or heat-treated steel for wear resistance and are replaceable. Ask the seller for details on disc diameter, thickness and part numbers for replacements.

7. How should I maintain the disc harrow?

Regular maintenance includes greasing bearings and pivot points, checking and tightening bolts, inspecting discs for wear or damage, replacing worn bearings/seals, and cleaning off corrosive residues after use or storage.

8. Can this implement be used on rocky or heavy clay soils?

Disc harrows work on a wide range of soils but performance and wear depend on soil conditions. For very rocky fields or extremely heavy clay, evaluate disc size, thickness and bearing protection, and consider slower speeds to reduce damage.

9. What towing/operating speed should I use?

Recommended working speed varies with soil type and tractor power. Operate at a steady, moderate speed that allows the discs to cut and rotate freely—consult the operator manual or supplier for model-specific guidance.

10. Does the unit fold for transport and what is the transport width?

Some three-point disc harrows have folding frames for transport while others are fixed. Transport width varies by model; request transport dimensions from the seller if transport width or road regulations are a concern.

11. What safety precautions should I follow?

Always shut off the tractor and lower the implement before performing adjustments or maintenance, wear appropriate PPE, ensure all guards are in place, and follow the tractor and implement manuals for safe hitching and operation.

12. Are spare parts and service available?

Availability of spare parts and service varies by supplier. Ask the seller about spare disc availability, bearings, blades, and local service support before purchase.

13. How many passes are typically needed to prepare a seedbed?

Seedbed preparation depends on soil condition, residue and crop needs. Often one to three passes are used: initial break-up, secondary smoothing, and finishing. Adjust passes based on field results and desired finish.

14. What is the expected field capacity or productivity?

Field capacity depends on working width, forward speed and field conditions. Use the formula: field capacity = (working width in meters × speed in km/h × efficiency factor) to estimate output, or ask the supplier for typical performance figures for this model.

15. Is there a warranty and what does it cover?

Warranty terms vary by manufacturer and seller. Common coverage includes manufacturing defects for a limited period; wear items (discs, bearings) are often excluded. Confirm warranty duration and terms with the seller prior to purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading