B21, China Town Mall, Midrand

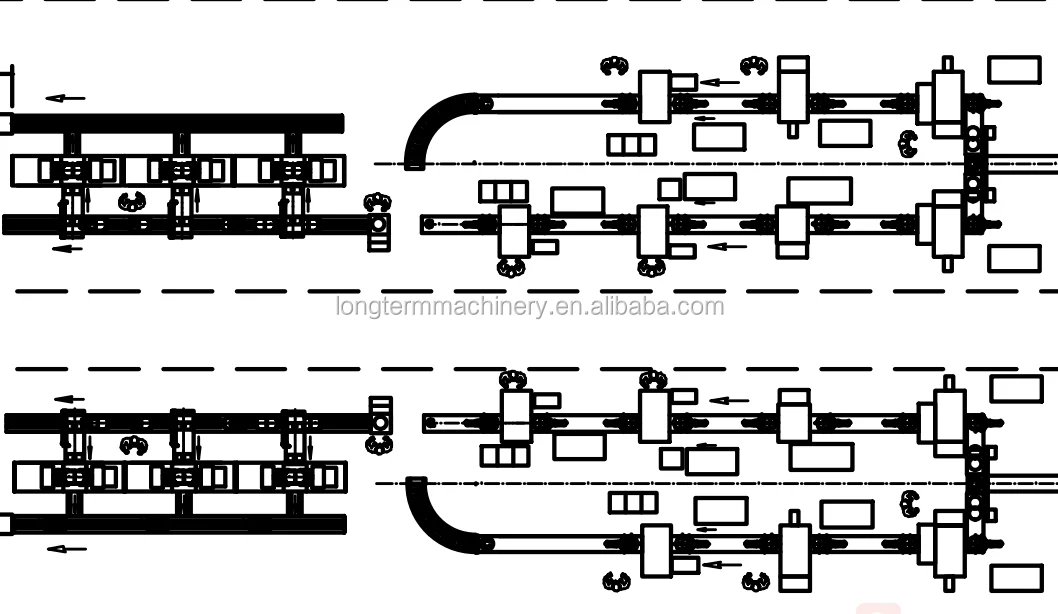

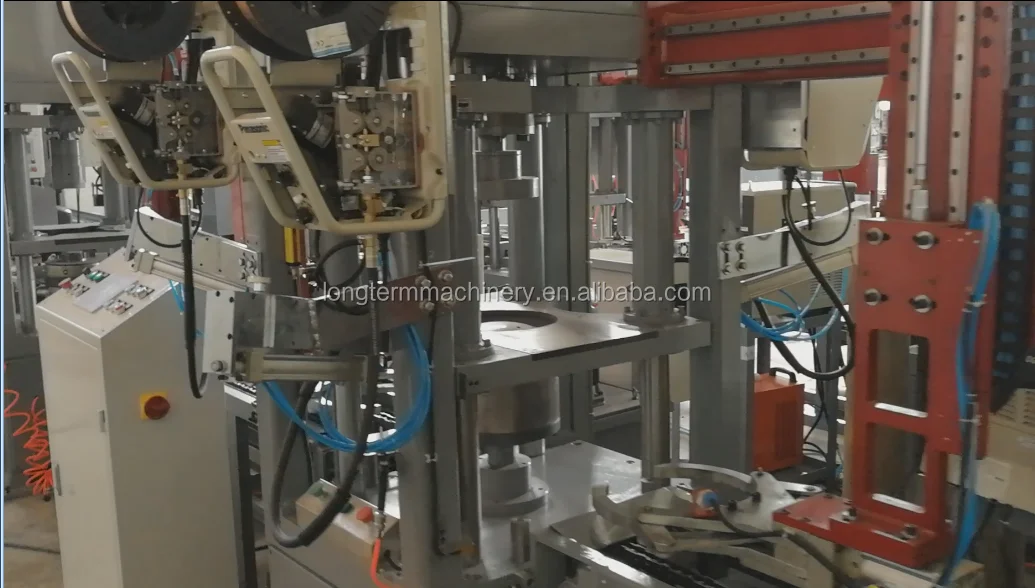

Africa LPG gas cooking cylinder production line, turnkey whole production line solution solver

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600200641451

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the production capacity of the Africa LPG gas cooking cylinder production line?

The production capacity varies based on the configuration and operational settings, but our full automatic line can achieve high efficiency and output rates, significantly reducing labor costs.

2. What types of welding machines are included in the production line?

The production line includes several machines for different welding processes, including socket welding, handle welding, base ring welding, and circumferential welding, all of which can be fully automated.

3. Is the production line customizable?

Yes, we offer both full automatic and semi-automatic configurations to suit different customer requirements and budget constraints.

4. What is the advantage of using a full automatic welding line?

A full automatic welding line enhances productivity by automating the welding processes, reducing labor costs, and improving overall working efficiency.

5. How does the automatic circumference welding work?

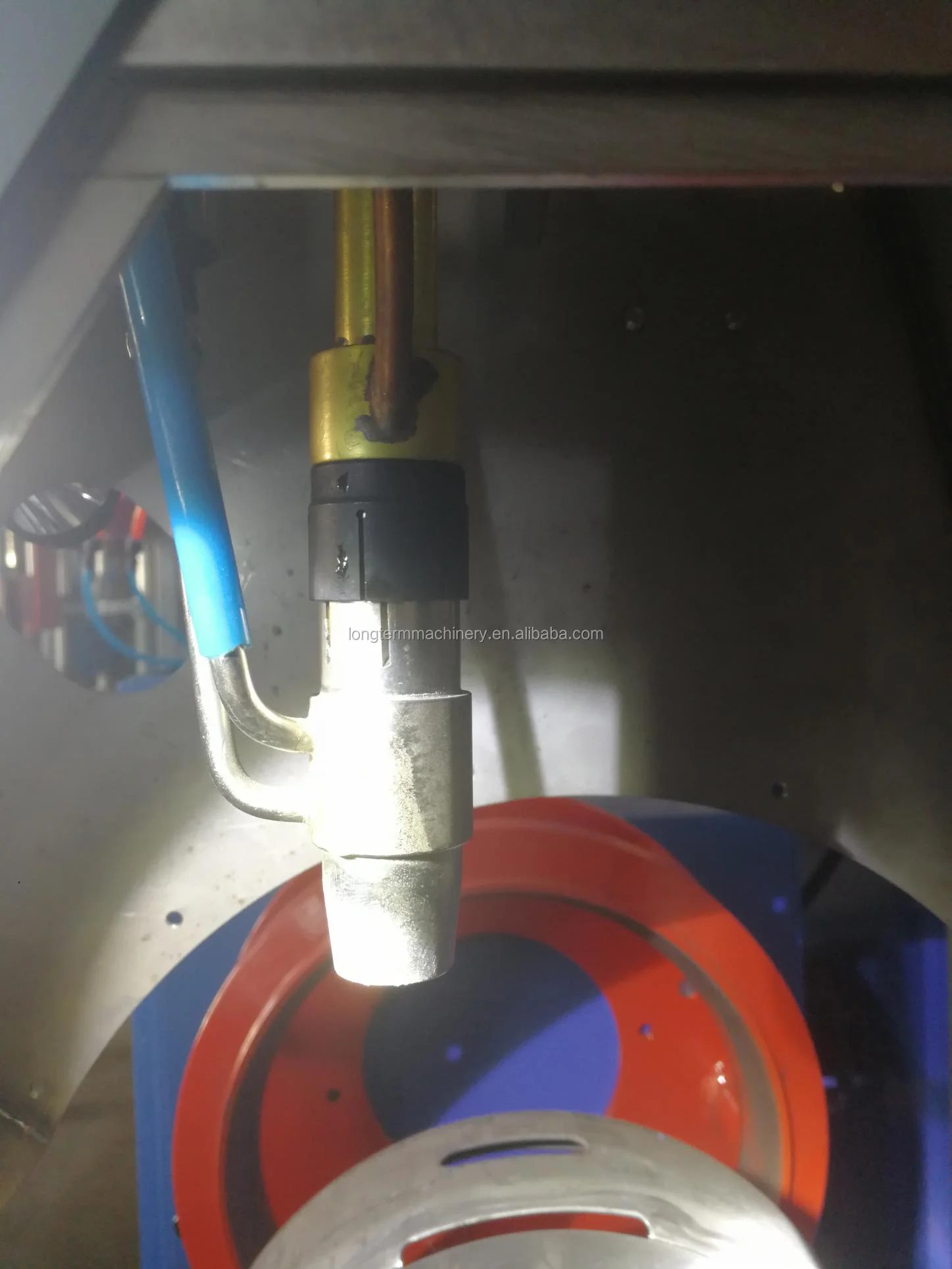

The automatic circumference welding uses a seamvision tracking device for automatic imaging and tracking of the welding seam, allowing for precise and efficient welding without manual intervention.

6. What safety features are included in the machines?

All machines are equipped with grating security protection to ensure the safety of operators during the welding processes.

7. What type of welding source is used in the production line?

The welding source includes high-speed pulse MIG welding technology, specifically the Panasonic 500GS, which is designed for efficient and high-quality welding.

8. Can the production line handle different cylinder sizes?

Yes, the production line can be configured to accommodate various LPG cylinder sizes, depending on the specific requirements of the customer.

9. What is the cooling system for the welding torches?

The production line includes a Supercooler automatic circulating cooling water tank that ensures the welding torches are cooled effectively during long welding operations.

10. What is the role of the hydraulic stations in the machines?

The hydraulic stations provide necessary pressure for the welding processes, ensuring that the welding torches operate efficiently and effectively during production.

11. How can I get support after purchasing the production line?

We offer comprehensive after-sales support, including installation, training, and maintenance services to ensure your production line operates smoothly.

12. What is the lead time for delivering the production line?

The lead time for delivery depends on the specific configuration and order volume, but we strive to provide timely delivery while maintaining high quality standards.

13. Can the production line be integrated with existing equipment?

Yes, our production line can often be integrated with existing equipment, depending on the specific setup and customer needs.

14. What kind of training do you provide for operating the production line?

We provide comprehensive training for operators, covering machine operation, safety protocols, maintenance, and troubleshooting to ensure effective usage of the production line.

15. What is the expected lifespan of the equipment?

With proper maintenance and care, the equipment in the production line is designed to have a long lifespan, providing reliable service for many years.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading