B21, China Town Mall, Midrand

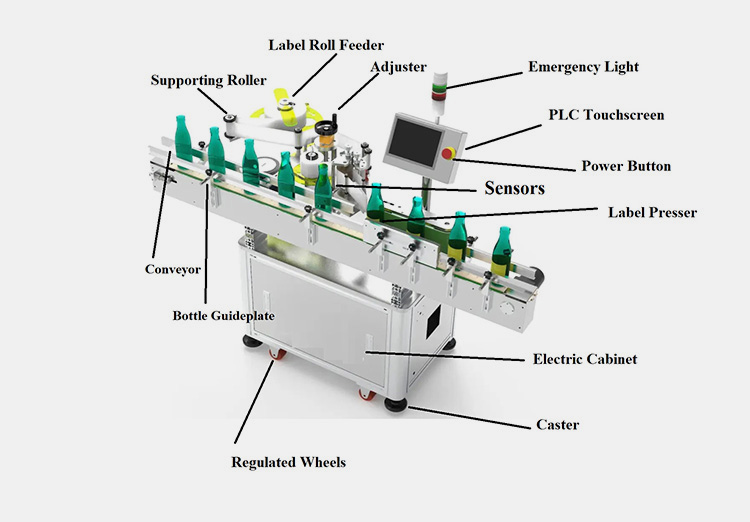

Adhesive Sticker Round Labeling Machine for Bottles, Jars, and Cans with Printer(cans)

- Section : Machinery

- Category : Packaging Machines

- SKU : 1600447019645

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of containers can the Adhesive Sticker Round Labeling Machine handle?

The machine is designed to label round bottles, jars, and cans with a diameter ranging from 28mm to 100mm and a height of 30mm to 260mm.

2. What is the labeling capacity of this machine?

The Adhesive Sticker Round Labeling Machine has a capacity of 20 to 230 pieces per minute, depending on the specific application and setup.

3. Can this machine print labels as well as apply them?

Yes, the machine features a visual camera detection function for printing content, allowing for seamless integration of printing and labeling.

4. Is this machine suitable for use in the pharmaceutical industry?

Absolutely! This labeling machine is essential for pharmaceutical applications, such as vial labeling and bill bottle labeling.

5. What optional features are available for this labeling machine?

Optional features include a turntable for infeed and outfeed, an additional labeling engine for uninterrupted operation, and sensors for label usage and product detection.

6. Can the machine be customized for different production lines?

Yes, the machine height can be customized to fit the specifications of your production line.

7. What power voltage options are available for this machine?

The Adhesive Sticker Round Labeling Machine operates on multiple voltage options: 110V, 220V, and 380V.

8. What type of labels can be used with this machine?

You can use adhesive stickers that are either transparent or opaque, with label dimensions ranging from 20mm to 250mm in height and 25mm to 300mm in length.

9. How does the machine ensure label accuracy?

The machine is equipped with check bottle sensors and opaque label sensors to ensure accurate labeling and prevent mislabeling.

10. What is the machine's driving mode?

The machine utilizes a servo motor along with a German NOVEXX labeling engine for precise and efficient operation.

11. What materials can be labeled with this machine?

The machine can label a wide range of materials, including those used in pharmaceuticals, cosmetics, food products, and chemical products.

12. Is technical support available for this machine?

Yes, our customer service team provides technical support to help with setup, operation, and troubleshooting.

13. What are the dimensions of the machine?

The machine has dimensions of 1800mm x 800mm x 1500mm.

14. Can the machine handle different label sizes?

Yes, the machine is designed to accommodate labels with varying sizes, specifically from 20mm to 250mm in height and 25mm to 300mm in length.

15. What are the main brands used in this machine's components?

The machine incorporates high-quality components from reputable brands, including SEMIENS for the PLC control system and touch screen, and German brands such as NOVEXX and JSCC for the labeling engine and motors.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals