B21, China Town Mall, Midrand

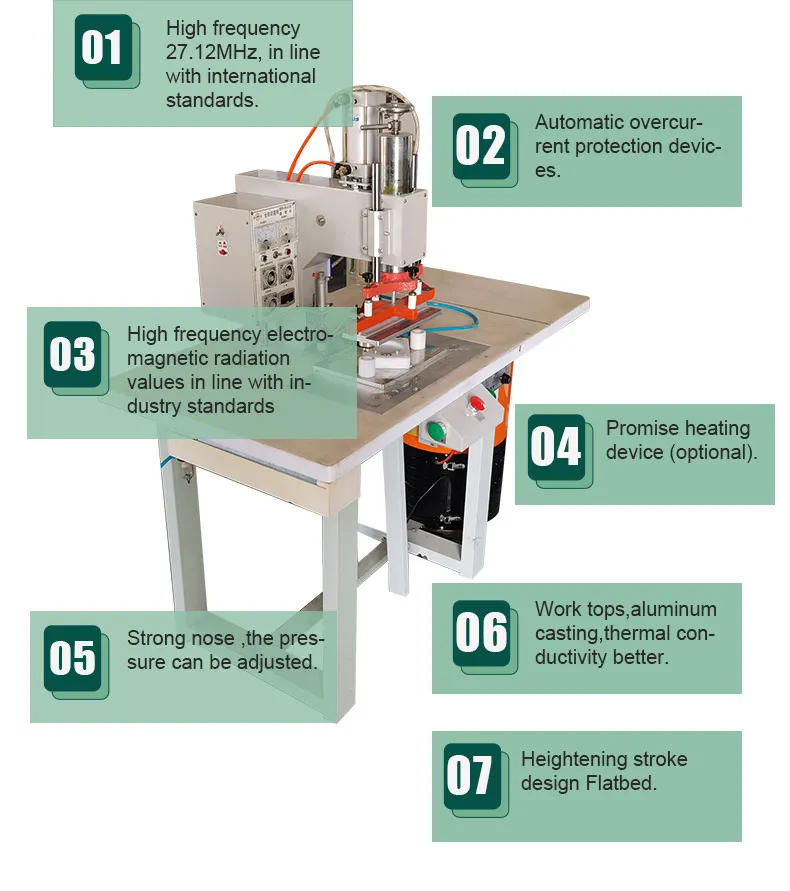

8 kw High Embossing Stamping Welding Machine for Leather Shoes Upper Embossing Mat Embossing

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600221617971

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the 8 kW High Embossing Stamping Welding Machine process?

This machine can process various plastic and leather materials, including PVC, TPU, EVA, and mixed materials, making it suitable for a wide range of applications.

2. What industries is this machine suitable for?

It is designed for industries such as footwear manufacturing, automotive interiors, medical supplies, and packaging, ensuring versatility in product manufacturing.

3. What are the key features of the 8 kW High Embossing Stamping Welding Machine?

Key features include high-frequency welding, precise temperature control, low maintenance requirements, high safety levels, and flexible manufacturing options.

4. What is the cooling method used in the machine?

The machine uses an air-cooled system for efficient cooling during operation.

5. What are the dimensions of the lower platen and on pressure side?

The lower platen size is 350 x 700 mm, and the on pressure side size is 320 x 180 mm.

6. What is the weight of the DZ-8000T/S model?

The DZ-8000T/S model weighs 380 kg.

7. Is customization available for specific manufacturing needs?

Yes, the machine offers tailored solutions for various products such as PVC carpets, lifejackets, tarpaulins, car mats, and more.

8. How does the machine ensure high-quality welding and embossing results?

It features advanced technology with high-frequency output and precise temperature control to achieve high-quality welding and embossing.

9. What is the supply voltage required for operation?

The required supply voltage for both models is 380V.

10. What is the oscillation frequency of the machine?

The oscillation frequency of the machine is 27.12 MHz.

11. How does the machine contribute to sustainability?

The machine is designed to be environmentally friendly, with low noise levels and low maintenance costs, contributing to sustainable manufacturing practices.

12. What is the mechanical activity capacity of the machine?

The machine has a mechanical activity capacity of 170 mm.

13. What are the model options available for this machine?

The available model options are DZ-5000T/S and DZ-8000T/S, with different high-frequency outputs.

14. How easy is it to operate the machine?

The machine is designed for ease of operation, making it suitable for both experienced operators and those new to the technology.

15. What makes the 8 kW machine different from the 5 kW model?

The primary difference is the power output; the 8 kW model provides higher power for larger scale operations compared to the 5 kW model.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading