B21, China Town Mall, Midrand

5TPH Alluvial Chrome ore Processing & Upgrading Plant

- Section : Machinery

- Category : Mining Machinery

- SKU : 2700004767682

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the capacity of the 5TPH Alluvial Chrome ore Processing & Upgrading Plant?

The plant has a processing capacity of 5 tons per hour (TPH).

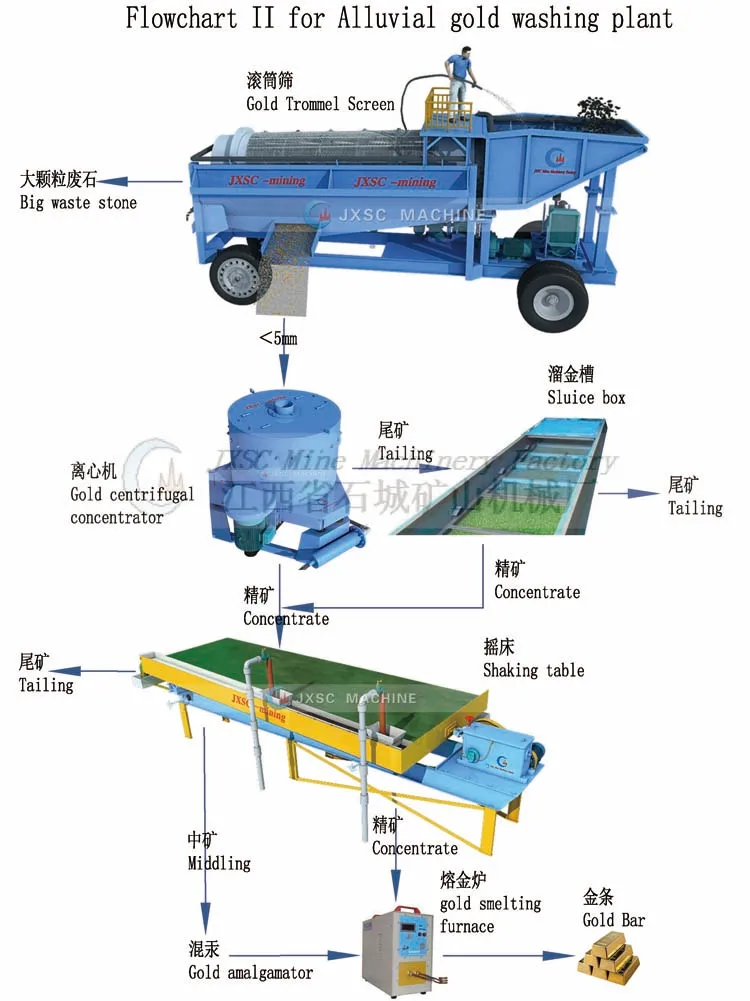

2. How does the rotary trommel screen work?

The rotary trommel screen operates by rotating materials inside a drum, allowing finer materials to pass through screen openings while larger materials exit through the rear end.

3. What are the advantages of using a trommel screen?

Trommel screens are economically viable, efficient, and designed for flexibility, allowing for easy operation, screen replacement, and effective material separation.

4. Can the screen mesh sizes be changed?

Yes, the trommel screen features changeable screen plates, allowing users to replace worn-out parts and adjust mesh sizes according to their needs.

5. What types of materials can be processed with this plant?

The plant is specifically designed for processing alluvial chrome ore, but it can also handle various other materials depending on the screen configurations.

6. What is the weight of the GT1015 model trommel screen?

The GT1015 model trommel screen weighs approximately 2,300 kg.

7. Is the plant suitable for small volume processing?

Yes, the 5TPH Alluvial Chrome ore Processing Plant is a highly economically viable option suitable for both small and large volume processing.

8. What are the dimensions of the GT1545 model trommel screen?

The GT1545 model has envelope dimensions of 5,960 mm in length, 1,900 mm in width, and 3,080 mm in height.

9. What power requirements does the plant have?

The power requirements vary by model; for instance, the GT1015 model requires 40 kW of power.

10. How does the design prevent material clogging?

The trommel screen is uniquely designed to facilitate higher capacities while providing longer screen life to minimize material clogging.

11. What is the under the screen size for the GT1225 model?

The GT1225 model has an under the screen size of 4 mm.

12. Are there multiple layers of screens in the trommel?

Yes, the trommel screen features multiple layers to enhance the sifting process and improve efficiency.

13. Can I see successful case studies of this plant in operation?

Yes, we can provide successful case studies showcasing the effectiveness of the 5TPH Alluvial Chrome ore Processing & Upgrading Plant.

14. What is the sieve tube diameter for the GT2055 model?

The GT2055 model has a sieve tube diameter of 500 mm.

15. How does the trommel screen enhance user experience?

The trommel screen's design focuses on simplicity and flexibility, making it easy to operate and customize based on user needs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals