B21, China Town Mall, Midrand

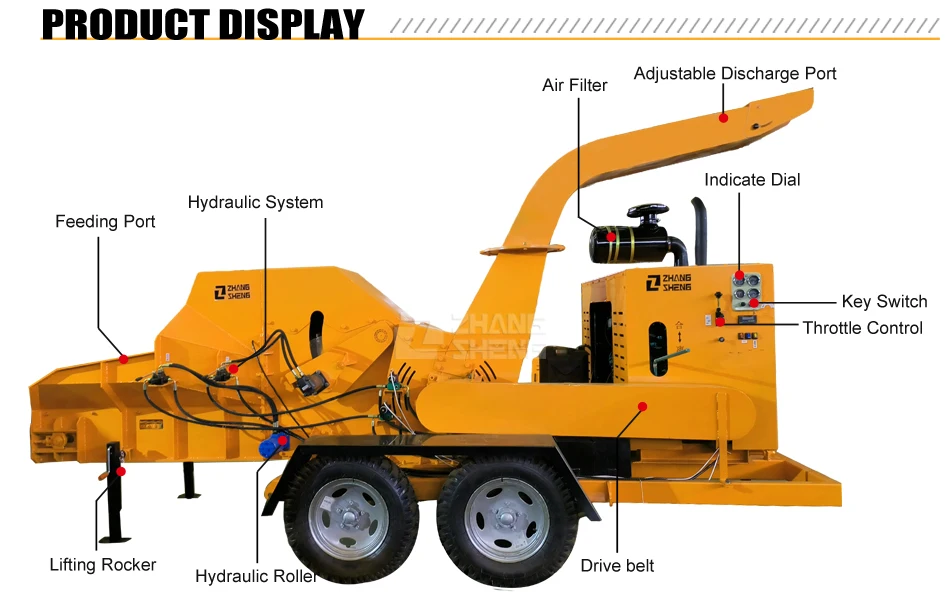

16 Inch High Efficiency BX 52 Wood Chopper 50 Tons Wood Chips Sieve Machine

- Section : Machinery

- Category : Woodworking Machinery

- SKU : 1601060428148

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

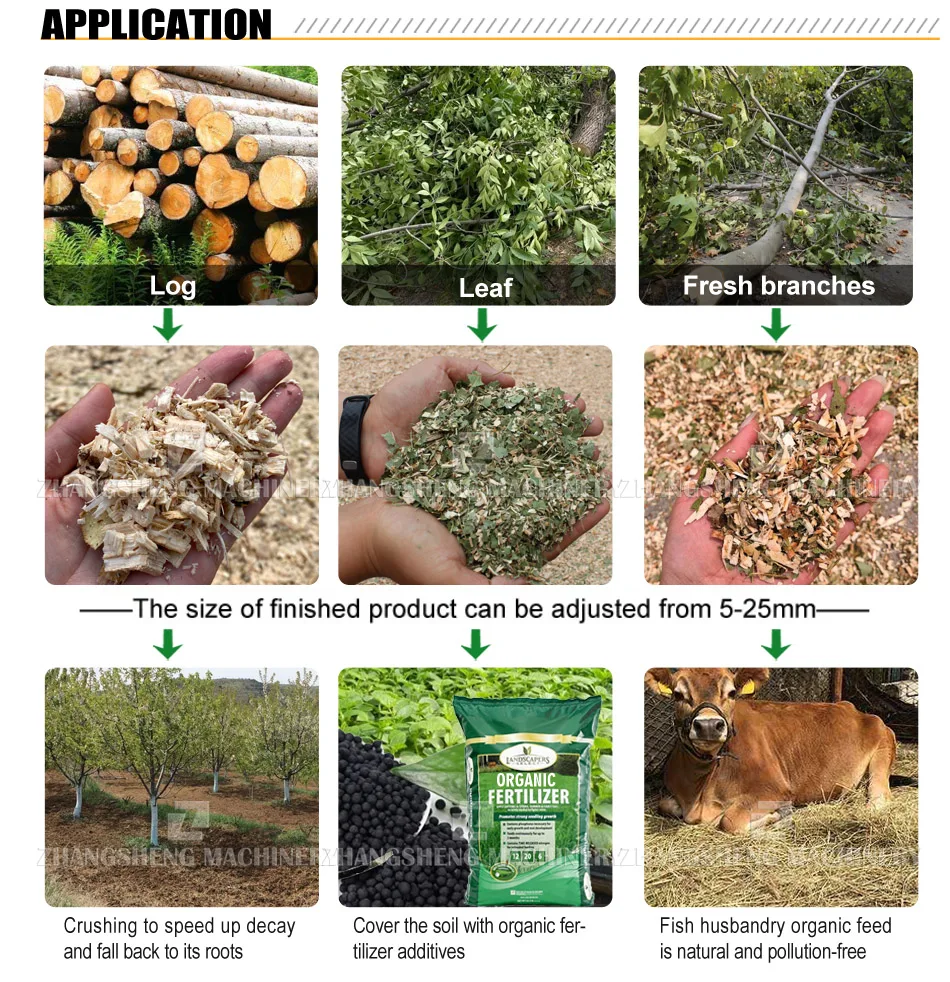

1. What is the throughput/output capacity of this wood chopper?

The machine can reach up to about 5,000 kg/hour (5 tons/hour) under optimal conditions. Actual output depends on wood species, moisture content, log diameter and selected model/configuration.

2. What maximum log diameter can the machine process?

Different model/configurations handle different diameters. Available maximum log diameters range from 150 mm up to 480 mm depending on the model—select the specific model to match your required max log size.

3. What engine types and power options are available?

The unit supports diesel engines or electric motor drives. Diesel engine power options span multiple ratings (examples in the range of ~54 HP up to ~336 HP). We also support well-known brands such as Cummins and Perkins as options.

4. What are the cutting drum sizes and blade quantities?

Multiple cutting drum sizes are offered (examples include Φ350×320, Φ480×500, Φ630×600, Φ850×700 mm). Blade counts vary with drum size (typical configurations include 4, 6, or 9 blades on the cutting drum) to suit different throughput and chip size requirements.

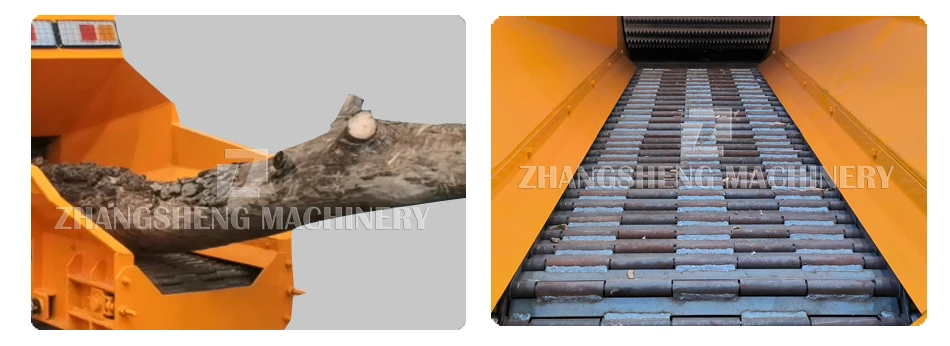

5. What feeding methods does the machine use?

Feeding options include manual feed, metal conveyor feed, and a hydraulic forced feeding system. The hydraulic system allows adjustable feeding speed, forward/reverse control of the chain plate, and can integrate with a log grabber for continuous feeding.

6. Does the machine have anti-jam or overload protection?

Yes. The intelligent control system automatically monitors crushing mechanism load. If the load exceeds preset alarm values, it will automatically reduce or stop feeding to prevent jamming and protect the drive train.

7. What monitoring and control features are included?

An intelligent control panel displays key parameters such as oil level, water temperature, and working hours. It provides status monitoring and makes starting and operation convenient with key-start capability.

8. How are the wood chips discharged and how far can they be thrown?

The machine has a 360-degree rotating discharge outlet. The wood chip discharge throw distance exceeds 3 meters, enabling direct loading into trucks or hoppers.

9. Is the machine mobile and easy to transport?

Yes. The unit can be trailer-mounted with a 3-inch trailer hitch and all-steel tires, allowing a small vehicle to tow a machine weighing around 4,000 kg for mobile operations. Additionally, detachable parts like the discharge nozzle and tires can be disassembled to reduce transport volume and cost.

10. Can this machine be used with a log grabber or other upstream equipment?

Yes. The machine is compatible with a log grabbing/loading machine. The intelligent feeding system and chain plate can be matched with grabbers for even, continuous feeding—capable of processing timber up to around 350 mm diameter efficiently when combined.

11. What materials and build quality features are highlighted?

The chain plate is made from Q235 carbon steel with high conveying capacity and load-bearing ability. The overall design emphasizes heavy-duty components and large-diameter drum rotors for direct chipping of larger logs.

12. How easy is blade maintenance or replacement?

Blades are mounted on the cutting drum and can be replaced as part of routine maintenance. Replacement frequency depends on wood type and usage. For safe, efficient servicing, follow the manufacturer's maintenance schedule and use recommended spare blades.

13. What safety features should operators be aware of?

Key safety features include the hydraulic feeding control with automatic overload protection, emergency stop capability on the control panel, and protective guarding around feed and cutting areas. Operators should follow PPE and lockout procedures during maintenance.

14. How do I choose the right model for my needs?

Select a model based on the maximum log diameter you need to process, desired throughput (kg/hr), available power source (diesel vs. electric), and whether you require mobile/towed operation. Contact the supplier with your material type, moisture content, and production targets for a recommended configuration.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals