B21, China Town Mall, Midrand

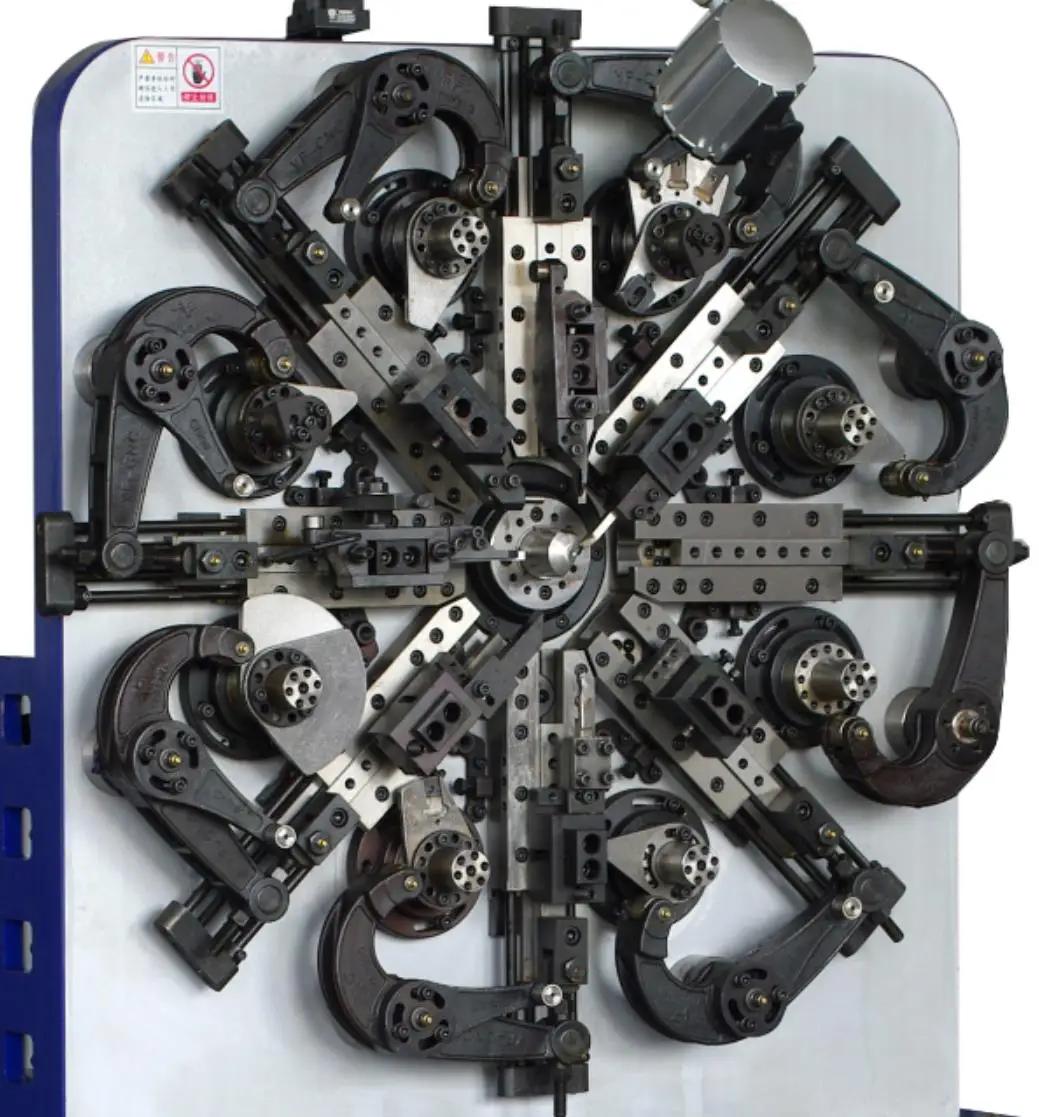

0.2mm-3.5mm spring file making machines,spring maker forming machine,spring wire making machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600590001273

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of springs can this machine produce?

This machine is suitable for producing various types of springs including double torsion springs, straight springs, pagoda springs, tension springs, rectangular springs, swirl springs, and other complex shaped springs.

2. What is the range of wire diameters this machine can handle?

The machine can work with wire diameters ranging from 0.2mm to 3.5mm.

3. How does the crimp function enhance processing speed?

The crimp function features a detachable installation that allows for faster processing, especially during corner processing and arc bending.

4. Can the machine’s settings be adjusted during operation?

Yes, parameters such as major diameter and angle can be modified at any time based on the working status displayed on the fluorescence screen.

5. What kind of control system does this machine use?

The machine is equipped with a Taiwan CNC control system and a Japan servo motor to ensure precise wire feed and high production quality.

6. What happens if a defective product is detected?

The machine has a precious inspection tracer device that automatically stops operation if an unqualified product is found.

7. Is the machine easy to operate?

Yes, the machine is designed for convenient operation with simpler forming processes and powerful functions for various spring types.

8. What is the unique feature of the machine’s tuner-core structure?

The tuner-core structure is uniquely processed to handle complex spring shapes without relaxing and requires no maintenance.

9. How efficient is the wire feed system?

The wire transfer system allows the entire wire feed to rotate 360 degrees in both forward and reverse directions, improving working efficiency.

10. Can the machine produce fancy and complicated shaped springs?

Yes, the machine is capable of producing fancy springs and complicated shaped springs, making it versatile for various applications.

11. What materials can be used with this spring making machine?

The machine is designed for use with spring wire materials, including steel and other suitable materials for spring production.

12. Is maintenance required for the machine?

The unique tuner-core structure requires no maintenance, but regular checks and cleaning are recommended to ensure optimal performance.

13. What is the maximum angle the machine can form?

The machine supports multiple angle forming, allowing for a wide range of angles to be achieved based on the spring design.

14. How does the machine improve debugging and setup?

The machine is designed for more convenient debugging and simpler operations, allowing for quicker setup times and adjustments.

15. What is the brand of this spring making machine?

This machine is branded as YF, known for its concentrated CNC spring machines with advanced features.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading